About Mechanical CAD

Enscape

Enscape

stands for "Computer Aided Design." AutoCAD is a two-dimensional and three-dimensional design software produced by the Autodesk Company. It is a computer-aided drafting software program used to create blueprints for buildings, bridges, computer chips,

machineries & products among other things. It includes a powerful suite of features to improve workflow and create true-to-life maps, diagrams,

structures and schematics. AutoCAD is used across a wide range of industries, by architects, project managers, engineers, graphic designers, and many other professionals.

LEARNING OBJECTIVE

* 2D Drafting.

* Drafting Setting Toolbar.

* Modifying Toolbar

* Annotation.

* Styles Managers.

* Layer.

* Palettes.

* Design Center.

* Geometric and Dimensional Constraints.

* Express Tools.

* Linking and Extraction.

* Plotting.

* 3D Modeling.

* Render,Animation.

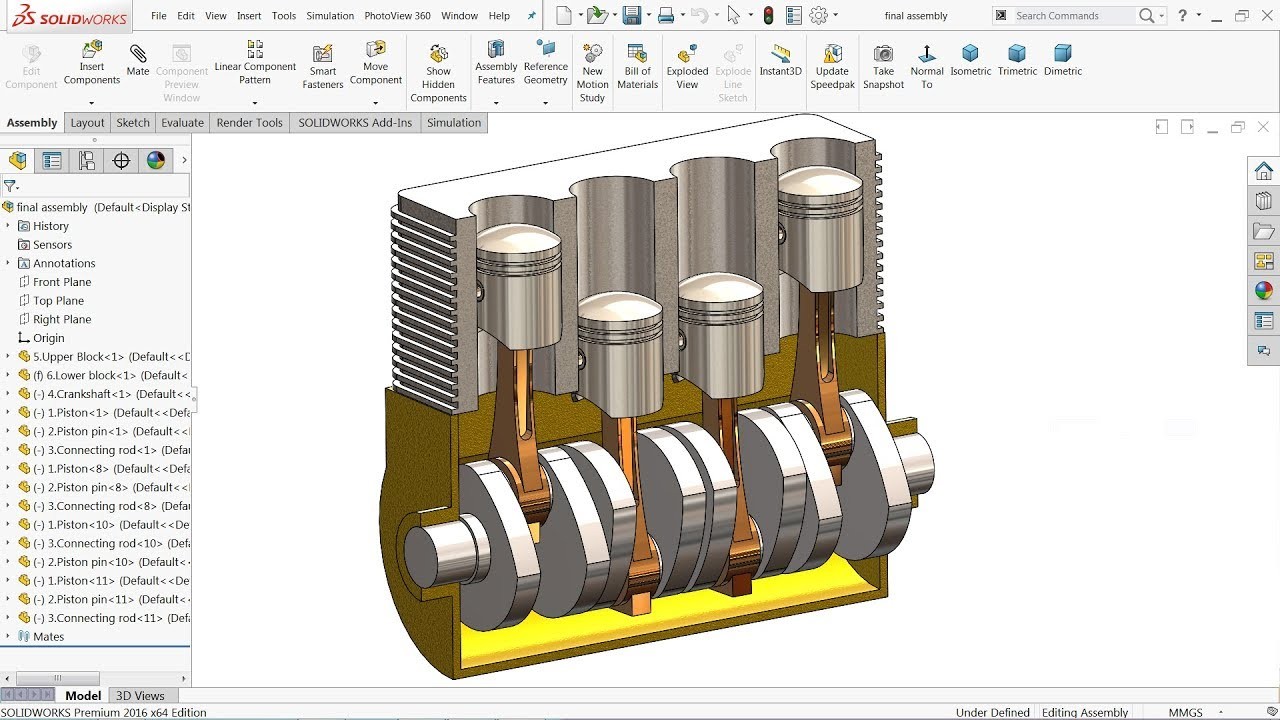

Solid Work

SolidWorks is a solid modeling computer-aided design (CAD) and computer-aided engineering (CAE) computer program. SolidWorks is published by Dassault Systems the makers of "Raffel" jets.

SolidWorks is a solid modeler, and utilizes a parametric feature-based approach to create models and assemblies. SolidWorks cover all aspects of your product development process with a seamless,

integrated workflow-design, verification, sustainable design, communication and data management. Designers and engineers can span multiple disciplines with ease, shortening the design cycle,

increasing productivity and delivering innovative products to market faster. SolidWorks standard offers great ease-of-use and performance in delivering robust 3D design capabilities.

Discover increased design productivity with SolidWorks Standard as you create fully detailed parts, assemblies, and production-level drawings and access all the tools required to generate

complex surfaces, sheet metal flat patterns, and structural welded assemblies. The biggest advantage of SolidWorks is, its user friendly approach. While Catia and Creo are useful in complex design, SolidWorks is widely used to design simple product and by low and medium scale industries.

LEARNING OBJECTIVES

* Introduction to solid works.

* Sketch entities

* Sketch modifying tools.

* Part modeling

* Reference geometry

* Advance modelling tool

* Introduction to assembly

* Applying advance mates

* Mechanical mates

* Dimensioning

* Tables

* Surface modeling

* Sheet metal design

* Import/export cad files to other software.

Catia V5

CATIA V5 is the leading solution for product development success. It addresses all manufacturing organizations, from OEMs through their supply chains, to small independent

producers. CATIA, for virtual product design, can be applied to a wide variety of industries, from aerospace, automotive, and industrial machinery, to electronics, shipbuilding,

plant design, and consumer goods. Today, CATIA is used to design anything from an airplane to jewellery and clothing. With the power and functional range to address the

complete product development process, CATIA supports product engineering, from initial specification to product-in- service, in a fully-integrated manner. It facilitates reuse

of product design knowledge and shortens development cycles, helping enterprises accelerate their response to market needs. CATIA lets users to design shapes and reach high levels

of surface sophistication with its 3D sketching, visualization features. With CATIA product developers can take an integrated systems engineering approach.

They can do requirements engineering, systems architecture definition, detailed modeling and simulation to manage the complex development process.

LEARNING OBJECTIVES

At CAD DESK, we help you master in the following capabilities of CATIA:

* GUI of CATIA V5.

* Workbenches of CATIA

* Sketcher

* Apply Material, Type of Materials

* Reference elements

* Transformation Features

* Boolean Operations

* Assembly

* Constraints

* Wireframe and Surface

* Generative Sheet Metal

* Cutting/Stamping

* Drafting

* Dimensioning

* Annotations.

NX-CAD

NX CAD software package originally developed by Unigraphics, But since 2007 managed by Siemens PLM software. NX enables you to freely use any modeling approach that fits your

design challenge. With the industry's most powerful and versatile CAD modeling tools, you can create and edit geometry with greater speed and flexibility.

Unlike CAD-only solutions and closed enterprise solutions, NX delivers the highest integration between development disciplines in an open, collaborative environment.

You can work faster and more efficiently in the full range of design tasks, from 20 layout through 3D modeling, assembly design, drafting and documentation.

NX design tools are superior in power, versatility and productivity. You can work faster and more efficiently in the full range of design tasks,

from 2D layout through 30 modeling, assembly design, drafting and documentation. NX assembly design tools are ready for the most complex assemblies,

even those with thousands of parts. You can create full multi-CAD digital mockups with NX to quickly identify issues and resolve problems.

LEARNING OBJECTIVES

* Interface of NX CAD

* Sketch

* Design feature

* Assembly

* Sheet metal

* Drafting

* View creation wizard

* custom symbol

* drawing format

NX CAM

NX CAM has a tightly integrated post processing system. Multiple levels of NC program validation include G-code driven simulation, which eliminates the need for separate

simulation par kages. NE CAM provides a wide range of functionality from sample NC programming to multi axis machining, enabling NC programmers to address many tasks using

one system. The flexibility of NX CAM means that the most demanding jobs can be completed easily also avalls wide range of 2 axis and 3-axis machining capabilities for prismatic

and freeform parts-ranging from manual tool path creation and editing to advanced, automated cotting methods 10 CAM provides a complete turning solution that is easy enough to

use on simple programs and capabile enough to tackle your toughest geometry in multispindle, multi tirret applications. Turning in NX can use either 20 part profiles or full

solid models. It includes routines for roughing, multiple pass finishing, grooving, thread cutting and centerline drilling NX automatically applies the right feeds and speeds

for a given operation and tosi selection. A key TEX CAM advantage facilitates integrated simulation and verification, which enables programmers to check tool paths within the

NC programming session, Multiple levels of capability are available.

LEARNING OBJECTIVES

* Types of manufacture process

* Types of milling operaбит

* Face milling operation

* Planar profile operation

* Planer text milling operation

* Mixed operation of planer mill

* Cavity milling operation

* Z-level milling operation

* Multi avis milling operation

* Multi blade avis operation

* Turning operation

* Drilling operation

* Counter boring operation

* Milling & turning mixed operation

Art CAM

ArtCAM is a collection of CAD/CAM software package for designing creative and artistic products and manufacturing. It is a CAM computer application especially used when the

user works on wood engraving machines or similar machines. This course explains about 2D and 3D inbuilt design features such as reliefs, engraving, sign making, etc.

ArtCAM is highly recommended software in a variety of sectors from jewellery and coin minting, to the design and manufacture of architectural cornicing and facades.

LEARNING OBJECTIVES

* Introduction to User Interface ArtCAM

* Design Tools

* Vector Creation and Editing

* Fill Tool

* Craving Tool Path

* Drilling Tool Path

* Relief Creation and Editing

* Bitmap Tools

* 3D Toolpath

Tech Taught Institute

A brand in Kingsway Camp

Call Us

Call Us--9582077309

* Sketch entities

* Sketch modifying tools.

* Part modeling

* Reference geometry

* Advance modelling tool

* Introduction to assembly

* Applying advance mates

* Mechanical mates

* Dimensioning

* Tables

* Surface modeling

* Sheet metal design

* Import/export cad files to other software.